Japanese Weaves and Knits

Japan is home to many textile producing regions. Broadly speaking, these regions focus on either weaves or knits. To produce woven fabric, two distinct sets of threads—the warp and the weft—are interlaced at right angles. Knit fabric is produced by creating a series of intertwined loops from a single strand of yarn. Weaves and knits each employ a different set of tools, and the look and feel of these two fabrics varies greatly depending on the type of thread and yarn used.

Clean, reliable water is essential for dyeing fibres and fabrics, and most areas with thriving textile industries are located near abundant sources of water. The Japanese islands run north to south in a long archipelago, and this topography has led over the centuries to textile production cultures suited specifically to different. Each culture produces a distinctive type of textile, from fabrics woven on looms so old they are no longer even manufactured, to fabrics produced with the latest cutting-edge technology in knitting machines. We invite you to experience all the allure of the weaves and knits crafted in Japan.

|

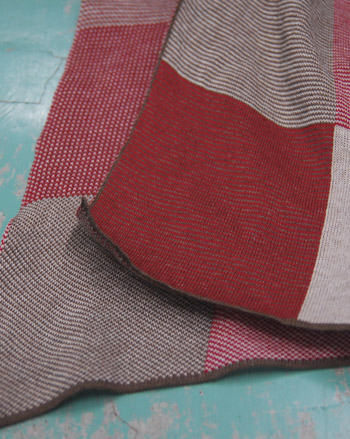

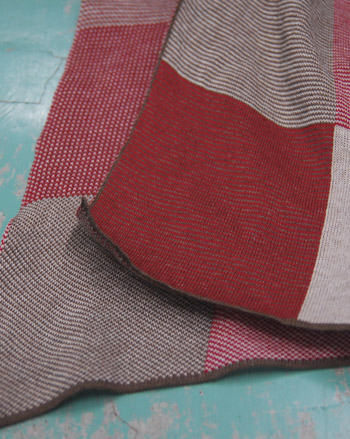

Wool Weaves

Ichinomiya City, Aichi Prefecture

The Bishu region, whose centre is Ichinomiya City in Aichi Prefecture, has been home to a thriving woven textile industry since the 8th century (Nara Period). With the clear water of the Kiso River flowing nearby, so well suited to fabric dyeing, the environment here is ideal for producing textiles.

The weaving process in the region is divided into specialisations, and each workshop focuses on one particular aspect of the process, be it prepping fibre, weaving, or finishing. This system of specialisation has produced a textile industry unlike any other. The old rapier looms still clatter away in the Bishu workshops today.

|

|

|

Wool yarn waiting to be warped onto the loom.

|

Only old rapier looms, and the master weavers who have spent their lives among them, can produce such distinctive texture and feel.

|

|

Whole Garment Knits

Ota City, Gunma Prefecture

To the north lies Kiryu City, a general textile production centre, and to the west lies Isezaki City, known for its meisen silk weaves. Between the two, Ota City in Gunma Prefecture is home to two distinct industries—the defence industry and the knit textile industry. This area was the first in Japan to introduce whole garment knitting machines, which produce distinctive knit fabrics using middle gauge and thicker yarns. Though small in scale, Ota knitters are busy producing special seamless knitwear,

from the initial fibre preparations to the finishing stages of the final product.

|

|

|

Scrap yarn is used to maintain tension during the

knitting process.

|

An expert knitter carefully picks up a stitch dropped by the knitting machine.

|

|

Intarsia Knits

Mitsuke City, Niigata Prefecture

Originally a weaving centre, Mitsuke City in Niigata Prefecture adopted knitting techniques from Tokyo, Nagoya, and other cities after World War II and grew rapidly to become a producer of knitted textiles. The area began with jersey knits for undergarments and now employs many different techniques to produce a wide variety of knits. One of these is the intarsia knit, a thin, light fabric in which the yarn is not carried across the back of the piece. Intarsia uses state-of-the-art technology and only together with a weaver’s touch at each step of the process, a truly quality knit can be produced.

|

|

|

The fabric is given a finishing wash to fluff it out for a

softer texture.

|

The final step (taking care of the ends) is always done by hand.

|

|

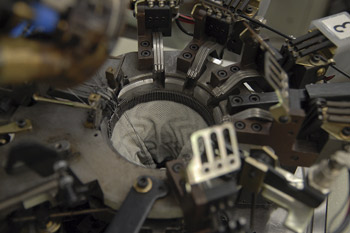

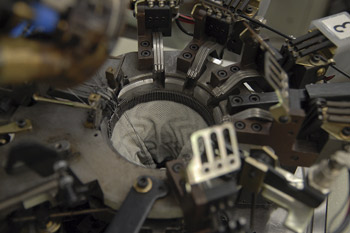

Circular Right-Angle Sock Knits

Shiki-gun District, Nara Prefecture

Shiki-gun in Nara Prefecture is the home of the sock-knitting industry in Japan, which developed as a cottage industry for farming families in the district in the second half of the 19th century. Although patterns were originally designed at a 90º angle to fit the shape of the heel, this angle expanded to 120º when industrialisation was introduced to raise productivity. The right-angle sock by MUJI brings back the comfort of the original sock, with heels that truly fit the contours of the foot. Knitting machine technology has progressed with the times, and socks are now machine-knit to a wide variety of patterns. Today, the looms in the Nara workshops are still at work 24 hours a day.

|

|

|

Many different types of yarn are used in knitting a single

pair of socks.

|

A peek inside a sock knitting machine that can knit a sock from start-to-finish with startling speed.

|

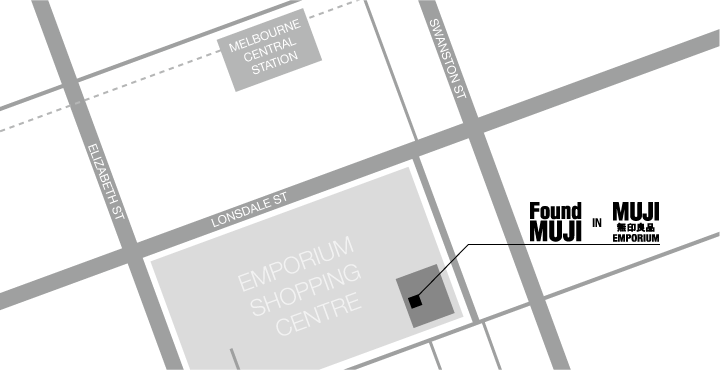

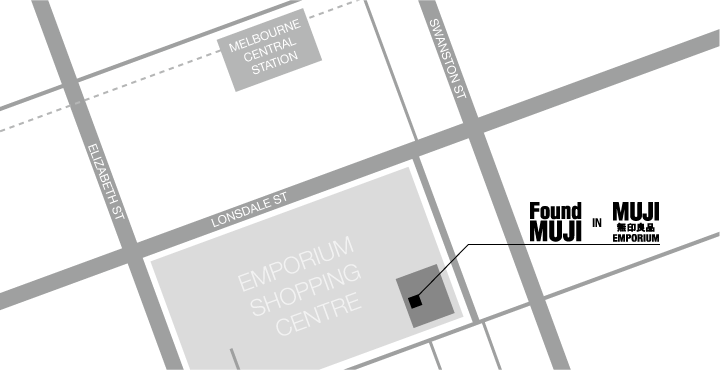

Found MUJI: MUJI Emporium

Level 2, Emporium Shopping Centre, 287 Lonsdale St, Melbourne, 3000

(▸ Store information)

![]()